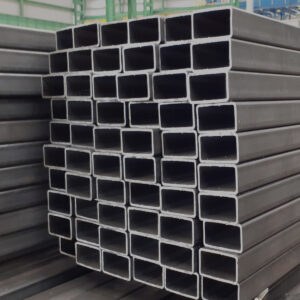

Best CRC Pipe Manufacturer in india

Cold Rolled Coil (CRC) pipes, also known as Cold Rolled Steel pipes, are widely used across industries for their superior strength, enhanced surface finish, and corrosion resistance. As a leading CRC pipe manufacturer, Jagdamba Enterprises is committed to delivering high-quality CRC pipes that meet the diverse needs of industries like construction, automotive, furniture, and more.

At Jagdamba Enterprises, we focus on precision, durability, and performance. With decades of experience in the field, we provide CRC pipes that are highly demanded for various applications, ensuring they meet the highest standards of quality. Whether you’re looking for standard sizes or customized CRC pipes for your specific project, we offer a wide range of options to cater to your requirements.

What are CRC Pipes?

CRC pipes are made from cold-rolled steel coils that undergo a process of cold rolling to achieve specific mechanical properties like dimensional accuracy, smooth surface finish, and high tensile strength. Unlike ERW (Electric Resistance Welded) pipes, CRC pipes are made using cold-rolling processes which help enhance their surface smoothness and thickness accuracy. These pipes are known for their uniformity, strength, and durability, making them ideal for a wide range of applications.

Why Choose Jagdamba Enterprises for CRC Pipes?

As a CRC pipe manufacturer with over 45 years of experience, Jagdamba Enterprises has built a reputation for quality and reliability in the industry. We supply CRC pipes that comply with international standards, ensuring that they perform optimally in their respective applications. Here’s why customers trust us:

Precision Manufacturing: Our CRC pipes are made using the latest technology and equipment, ensuring that each pipe meets the exact specifications required by the industry.

Customization: At Jagdamba Enterprises, we understand that each project has unique requirements. We offer customized CRC pipes, available in different sizes, thicknesses, and finishes to suit your specific needs.

Competitive Pricing: We believe in offering our high-quality CRC pipes at highly competitive prices, making sure you get value for your money without compromising on quality.

On-Time Delivery: We are committed to delivering CRC pipes on time, ensuring that your projects proceed without delay.

Durability: Our CRC pipes are designed to withstand harsh environments and offer long-lasting performance, making them ideal for industries like construction, automotive, and more.

Applications of CRC Pipes

CRC pipes find widespread use across several industries due to their versatile nature. Some of the common applications include:

Construction & Infrastructure: Used in the construction of buildings, bridges, railways, and other infrastructure projects for their strength and corrosion resistance.

Automotive Industry: Utilized in automotive frames, axles, and chassis components due to their high tensile strength.

Furniture & Fabrication: CRC pipes are commonly used in manufacturing furniture like tables, chairs, and other fabrication projects due to their ease of shaping and durability.

Gas & Water Pipelines: CRC pipes are ideal for water and gas pipelines due to their corrosion-resistant properties.

Agricultural Implements & Machinery: These pipes are used in making agricultural implements, solar tracking systems, and machinery parts.

Energy & Power Distribution: CRC pipes are essential in power distribution and energy sectors because of their durability and ability to withstand extreme conditions.

Benefits of Using CRC Pipes

Enhanced Surface Finish: CRC pipes come with a smooth surface finish, making them more aesthetically pleasing and resistant to corrosion.

Superior Strength: The cold-rolled manufacturing process imparts superior strength and makes CRC pipes ideal for handling high-pressure systems.

Corrosion Resistance: CRC pipes exhibit excellent resistance to rust and corrosion, even in extreme environments, making them perfect for both indoor and outdoor applications.

Accuracy and Precision: The cold-rolling process ensures dimensional accuracy and uniformity in the pipes, which is essential for high-precision industries.

Customization: We offer a wide range of sizes, thicknesses, and finishes, providing customized solutions that meet the exact needs of your project.

Why Jagdamba Enterprises is a Trusted CRC Pipe Manufacturer

At Jagdamba Enterprises, we believe that quality is paramount. With our state-of-the-art manufacturing facility and a team of skilled professionals, we ensure that every CRC pipe we produce adheres to international quality standards. Our integrated quality management systems monitor every step of production, from sourcing raw materials to final inspection, ensuring that only the highest-quality products reach our customers.

As one of the leading CRC pipe manufacturers in India, we have established long-term relationships with our clients due to our commitment to quality, customer satisfaction, and timely delivery. Whether you are looking for CRC pipes for residential, industrial, or commercial applications, Jagdamba Enterprises is your trusted partner.

FAQs About CRC Pipes

What are CRC pipes made of?

CRC pipes are made from cold-rolled steel coils that are processed to achieve specific mechanical properties such as strength, corrosion resistance, and dimensional accuracy.What is the difference between CRC pipes and ERW pipes?

The main difference between CRC pipes and ERW pipes lies in the manufacturing process. CRC pipes are cold-rolled and do not have any welding seams, while ERW pipes are made by welding steel coils.What are the advantages of using CRC pipes?

CRC pipes offer several benefits, including a smooth surface finish, superior strength, corrosion resistance, and high dimensional accuracy. They are widely used in various industries due to their reliability and durability.Can CRC pipes be customized?

Yes, CRC pipes can be customized in terms of size, thickness, and surface finish. Jagdamba Enterprises offers tailored solutions to meet your specific requirements.Where can CRC pipes be used?

CRC pipes are used in a wide range of industries, including construction, automotive, furniture manufacturing, plumbing, agriculture, and energy sectors. They are suitable for both structural and functional applications.

High Quality

Presence of an In-house Research & Testing facility ensures each Jagdamba 120 product confers to stringent quality norms.

Satisfaction

Trust of the customer is our most precious assets and we go a long way in delivering the best of it.